As industries evolve, the demand for scalable manufacturing solutions becomes more pronounced, especially in the nonwoven fabric production sector. One of the most pressing questions for businesses considering an investment in a spunbond nonwoven machine is whether it can grow alongside their expanding production needs. The answer lies in the design, flexibility, and technical capabilities embedded in the machine’s structure, offering the potential to adapt to rising production demands with minimal intervention.

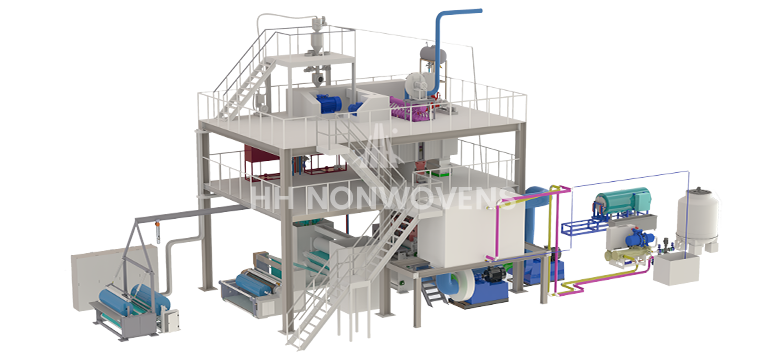

A key feature of the spunbond nonwoven fabric machine from Jiashan HH Nonwovens Machinery Co., Ltd. is its modular approach, which makes scalability a highly achievable goal. The machine's core structure is designed with flexibility in mind. For example, the system allows for easy adjustments to accommodate varying fabric widths, which range from 1600mm to 4200mm. This adaptability makes it possible to scale up production without needing to invest in entirely new equipment. The ability to change fabric widths and adjust output levels with minimal effort ensures that the machine can meet both current and future demands.

Additionally, the high degree of automation in the machine’s design further enhances scalability. The use of PLC controls and touch-screen operation simplifies the process of modifying production settings, such as machine speed and fabric weight, to align with changing production targets. As your business grows, the machine can be easily tuned to handle higher volumes, even with different materials, such as recycled polypropylene or specialized fibers. This flexibility makes it possible to keep pace with a growing market while avoiding costly modifications or equipment replacements.

Another important consideration is the use of high-quality components, including Siemens motors and ABB drivers, which provide the robustness and reliability required for sustained high-speed operation. The durability of these components ensures that the machine can continue to perform at optimal levels as production demands increase, and with a little investment in additional support systems like slitting or winding units, the production line can expand efficiently without interruption. Furthermore, the machine’s design is built for longevity, with key components such as rollers and motors designed to withstand extended use, making it well-suited for scaling production over time.

In short, the spunbond nonwoven machine is more than just a solution for today’s needs; it is an investment in future growth. With its adaptable design, modular capabilities, and reliable high-speed performance, this machine can be seamlessly scaled to handle greater production volumes, ensuring that your business remains competitive and agile in an ever-demanding market. Whether you’re looking to ramp up production for a specific product line or diversify your offerings, the flexibility built into this machine ensures it will support your business growth for years to come.

English

English 中文简体

中文简体 русский

русский عربى

عربى