Can Your Spunbond Nonwoven Machine Handle Materials Like PET or PLA?

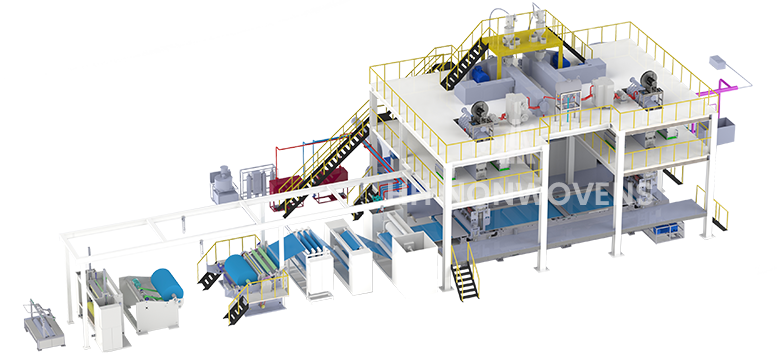

When investing in a nonwoven fabric production line, many manufacturers are looking for flexibility. After all, industries constantly evolve, and raw material preferences shift over time. If you're wondering whether a PP spunbond nonwoven machine can handle more than just polypropylene (PP), like PET or PLA, the answer is: it depends, but there's a lot to consider. Let’s break it down.

PP spunbond machines are specifically designed with polypropylene granules in mind. The process of converting these raw materials into fabric involves high temperatures and precise control over the extrusion process, which is optimized for PP's properties. So, if you're using just PP, the machine is running smoothly, and the settings are dialed in to produce fabrics with consistent quality and high efficiency.

But what about other materials like PET (polyethylene terephthalate) or PLA (polylactic acid)? These materials present unique challenges because their melting points, flow characteristics, and even fiber formation processes differ from those of polypropylene. PET, for example, has a higher melting point, which means the machine needs to be capable of handling those elevated temperatures without compromising the integrity of the components. PLA, on the other hand, behaves differently in terms of viscosity and flow rate, and can sometimes be trickier to process, especially in terms of bonding fibers together effectively.

That being said, many modern spunbond machines, particularly those designed with versatility in mind, are built with adjustable settings and components that allow them to process a variety of materials. Some machines are equipped with advanced heating systems and extruders that can handle higher processing temperatures required for materials like PET. Additionally, some machines come with interchangeable parts or customizable settings, which allow the user to fine-tune the process for different raw materials. For example, the filament denier can be adjusted, and the speed settings can be tweaked to accommodate the different properties of PLA or PET.

In essence, while the base design of a PP spunbond machine may be optimized for polypropylene, manufacturers can often modify these machines or invest in specific upgrades to process other raw materials. However, it's important to note that not all machines are built the same, and some may require significant modifications to handle more complex materials like PET or PLA. The key is ensuring that the extruders, temperature controls, and other critical components are up to the task, and that the machine's automation and control systems can handle the nuances of different fibers.

For businesses looking to diversify their product lines or respond to changing market demands, investing in a flexible nonwoven machine can be a game changer. While it may come with an additional investment upfront, it can pay off in the long term by allowing you to stay ahead of material trends and expand into new markets. It’s all about striking the right balance between machine capability, raw material adaptability, and the long-term needs of your business.

So, if you're looking at purchasing a spunbond nonwoven machine and you're thinking about branching out beyond PP, it’s worth having a conversation with the manufacturer about the potential for handling materials like PET or PLA. With the right machine, you can make your production line more versatile, and better positioned to meet the demands of a rapidly changing industry.

English

English 中文简体

中文简体 русский

русский عربى

عربى