Essential Skills for Operating a Spunbond Nonwoven Machine Efficiently

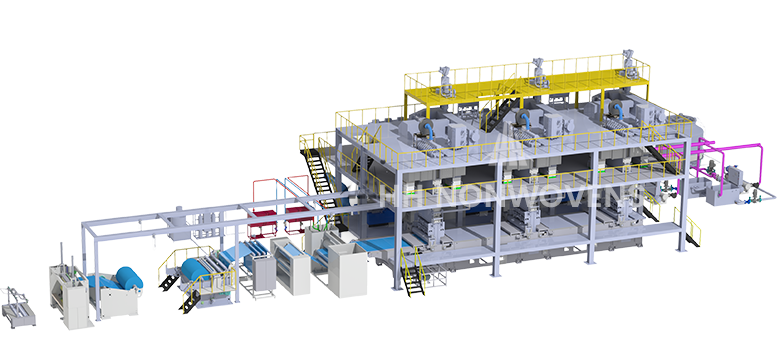

Operating a spunbond nonwoven machine is not just about pressing buttons and running the machine—it's about understanding the complexities of its automated systems, material handling, and maintenance protocols. While the machinery is designed to be user-friendly, the level of expertise required for operators depends on several key factors, including the machine’s technological sophistication, the specific fabric requirements, and the efficiency expectations of the production line.

At the core, an operator needs to have a strong understanding of the machine’s control systems, particularly the PLC (Programmable Logic Controller) and its touchscreen interface. These systems are designed to streamline operations, but to truly leverage their capabilities, operators must know how to troubleshoot minor glitches and adjust settings on the fly. Understanding the basic flow of the production process—from the raw material input to the final nonwoven fabric output—is essential for ensuring smooth operations and meeting quality standards. The more experience the operator has with the technical aspects of the system, the better they can optimize production and handle unexpected challenges.

Moreover, familiarity with the various production settings is critical. Operators should be comfortable adjusting parameters like machine speed, filament denier, fabric weight, and raw material types. For instance, switching between different fabric compositions or adjusting the density of the fabric might require nuanced knowledge of how these variables interact with machine settings. Operators need to know when and how to modify these parameters based on the desired outcome, which ensures not only consistency but also minimizes waste and downtime.

While the machine itself is designed for high automation, understanding the importance of regular maintenance and how to execute basic preventive care is just as crucial. Operators are usually the first line of defense in identifying potential issues before they escalate into costly repairs. Basic mechanical knowledge—like knowing how to inspect rollers, clean the system, and check motor functions—can greatly extend the lifespan of the machine and ensure production runs efficiently.

Running a spunbond nonwoven machine is a balance of practical hands-on skills and a strong grasp of technical principles. It’s not just about knowing how to operate the machine—it’s about understanding the relationship between materials, settings, and production flow. With proper training and experience, operators can manage the complexities of this machine efficiently, helping to maintain the consistency and quality of the product while optimizing production output.

English

English 中文简体

中文简体 русский

русский عربى

عربى