Exploring the Flexibility of Spunbond Nonwoven Machines with Different Raw Materials

Spunbond nonwoven machines are essential for the production of versatile and high-performance fabrics, particularly when working with polypropylene (PP) as the primary raw material. However, as industries evolve, the demand for sustainability and material flexibility is increasing. This raises an important question: Can a Spunbond Nonwoven Machine handle different raw materials besides polypropylene, such as PET or recycled materials, and how does this affect its performance?

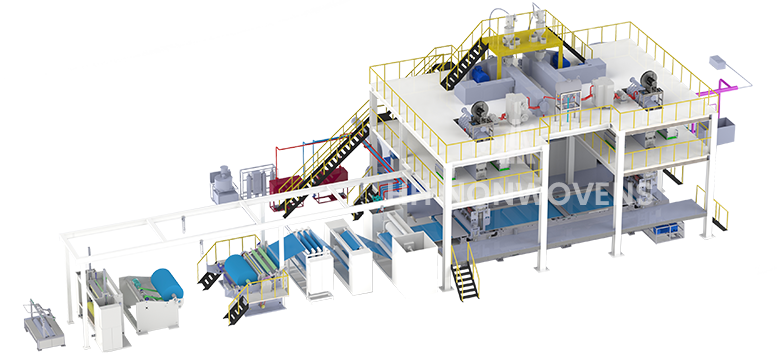

While polypropylene is the most common material used in spunbond nonwoven production due to its excellent balance of cost, strength, and versatility, the machine's ability to process alternative materials like polyethylene terephthalate (PET) or recycled fibers can significantly expand its application scope. Machines like the one described by Jiashan HH Nonwovens Machinery Co., Ltd are designed to be flexible, accommodating various raw materials, though adjustments and considerations must be made for the best results. When introducing new materials such as PET or recycled fibers, there are several aspects that need attention to ensure the machine operates efficiently and produces high-quality fabric.

One of the key considerations when using non-polypropylene raw materials is the processing temperature. Different polymers have varying melting points, and the Spunbond Nonwoven Machine must be capable of adjusting its heating system to accommodate these differences. For example, PET typically has a higher melting point than PP, which means the machine's heating components and extrusion systems must be calibrated accordingly. This ensures the fiber formation process remains smooth and consistent, avoiding issues like clogging or uneven fiber spreading. Additionally, materials like recycled fibers may have a lower consistency in quality due to impurities or variations in polymer blends, which could influence the final fabric quality.

Another consideration is the fiber bonding process. For the machine to produce high-quality nonwoven fabrics, it relies on the spinning and bonding mechanisms that fuse the fibers together. When switching to alternative materials, the bonding strength and uniformity may change. PET, for instance, tends to be stiffer than polypropylene, which may require adjustments in the air system, spinning speed, or bonding pressure. Similarly, recycled fibers might be more prone to defects like brittleness or inconsistency in fiber length, which could lead to weaker or less uniform fabric. However, modern Spunbond Nonwoven Machines are equipped with advanced technologies like dynamic roller balancing and CNC-precision manufacturing of critical parts, which help minimize these challenges and maintain high-speed, high-quality output.

The integration of Siemens motors and Siemens or ABB drivers in these machines plays a crucial role in managing performance when working with different raw materials. These high-performance motors offer precision control over the spinning process, enabling the machine to adjust speeds and processing parameters in real-time based on the material’s behavior. With the right adjustments, including changes to the air flow, cooling systems, and spinneret designs, the machine can handle the varying demands of different raw materials without compromising on output quality or efficiency.

Moreover, recycling PET or other materials can also present unique opportunities for businesses. Many Spunbond Nonwoven Machines are designed to accept recycled materials, making them not only adaptable but also an environmentally friendly choice. However, the raw material's quality must be carefully controlled to prevent issues like contamination, which could lead to uneven fabric characteristics. The ability to handle recycled materials is especially beneficial in industries focused on sustainability, where manufacturers are under pressure to reduce waste and use more eco-friendly alternatives. The fabric produced from recycled materials may sometimes have different texture or color variations, but with the proper adjustments to machine settings, these fabrics can still meet high industry standards.

Ultimately, the ability of a Spunbond nonwoven machine to handle different raw materials besides polypropylene, including PET and recycled fibers, is largely dependent on the machine’s flexibility and the adjustments made to the production process. While using alternative materials can introduce challenges in terms of processing conditions, fiber bonding, and final fabric quality, modern machines are equipped to manage these variations. With the right set-up, manufacturers can successfully switch between materials without compromising on performance or fabric properties. The advanced features of the Jiashan HH Nonwovens Machinery Co. line, such as high automation, PLC control, and precision engineering, allow for easy adaptation to different materials, providing companies with the versatility to meet diverse market demands while maintaining optimal production efficiency.

In conclusion, yes, the machine can handle different raw materials like PET and recycled fibers, provided the necessary adjustments are made to the processing conditions. With the correct settings and equipment optimizations, it’s possible to produce high-quality nonwoven fabrics from a variety of materials, making the machine a highly flexible and adaptable tool in the nonwoven fabric manufacturing industry.

English

English 中文简体

中文简体 русский

русский عربى

عربى