How do you maintain and troubleshoot a spunbond nonwoven machine?

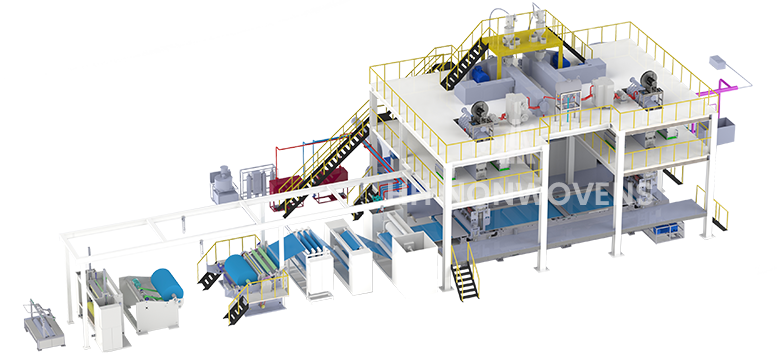

Maintaining and troubleshooting a spunbond nonwoven machine is crucial for ensuring consistent quality and efficiency in fabric production. Spunbond nonwoven machines are complex systems that convert polymer granules into nonwoven fabrics through a series of intricate processes. These machines require careful upkeep and prompt problem-solving to prevent downtime and maintain optimal performance.

Routine maintenance begins with regular inspections of key components such as the extruder, spinneret, and calendar rolls. The extruder, which melts and feeds the polymer, should be checked for signs of wear and tear or blockages that could affect throughput. The spinneret, where molten polymer is extruded into filaments, needs to be cleaned frequently to avoid clogging, which can cause uneven fiber formation. The calendar rolls, which bond the fibers into a fabric, should be aligned correctly and checked for surface damage that could compromise fabric quality. Lubrication of moving parts is also essential to minimize friction and wear, and the machine's bearings, gears, and chains should be inspected and lubricated according to the manufacturer’s recommendations.

In addition to mechanical components, the machine’s electrical systems must be regularly reviewed. This includes checking the main motors and drivers—often from reputable brands like Siemens or ABB—for signs of malfunction. Ensuring that electrical connections are secure and that control panels are functioning correctly is crucial for maintaining consistent operation. The machine's control system, typically operated via a PLC with a touch-screen interface, should be monitored for any error messages or malfunctions, which could indicate issues with the software or sensors.

Troubleshooting begins with a systematic approach to identifying and resolving issues. Common problems include inconsistent fabric quality, production interruptions, or abnormal machine noises. For fabric quality issues, operators should first check for any inconsistencies in the polymer feed or extruder temperature, as these can affect fiber formation. Regular calibration of the spinneret and calendar rolls can address issues such as uneven fabric thickness or bonding problems. Production interruptions may be caused by blockages or mechanical failures, which require inspecting and cleaning components like the spinneret and extruder.

In the event of abnormal machine noises, it’s essential to pinpoint whether the source is a mechanical issue, such as a worn-out bearing or misaligned roll, or an electrical problem. Listening carefully to the type of noise and cross-referencing it with the machine’s maintenance manual can help in diagnosing the issue. For more complex problems, such as those related to the control system or electrical components, consulting with the machine's manufacturer or a trained technician may be necessary.

Preventive maintenance practices, such as adhering to the recommended maintenance schedule and using high-quality parts and lubricants, can significantly reduce the frequency and severity of issues. Keeping detailed records of maintenance activities and any problems encountered helps in identifying recurring issues and planning for future improvements.

The effective maintenance and troubleshooting of a spunbond nonwoven machine involve a blend of routine inspections, mechanical and electrical upkeep, and systematic problem-solving. By following these practices, operators can ensure the longevity and efficiency of the machine, leading to high-quality fabric production and reduced downtime.

English

English 中文简体

中文简体 русский

русский عربى

عربى