How does investing in a spunmelt machine compare with other nonwoven production technologies in terms of cost-effectiveness?

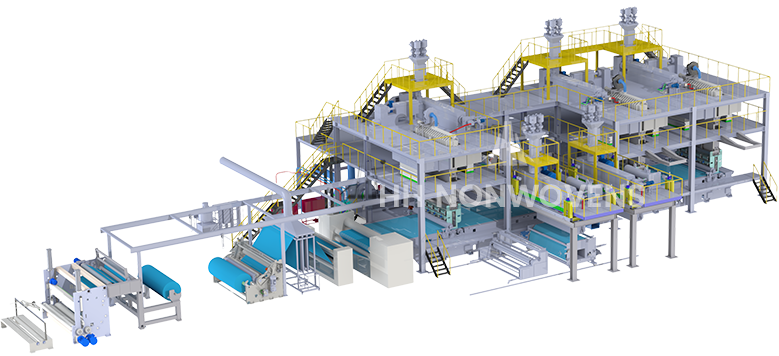

Investing in a spunmelt machine represents a strategic decision for businesses involved in nonwoven fabric production, and evaluating its cost-effectiveness compared to other nonwoven technologies is crucial for informed decision-making. Spunmelt machines, which combine spunbond and meltblown technologies, offer a versatile approach to fabric production. They can produce fabrics with various properties suitable for a range of applications, from medical masks to diapers and high-quality garment materials. The primary advantage of spunmelt technology lies in its ability to deliver high-quality fabrics with precise control over material properties, thanks to its dual-function capability and advanced automation systems.

In terms of cost-effectiveness, spunmelt machines generally present a favorable return on investment. The integration of spunbond and meltblown processes into a single line reduces the need for multiple machines, thereby lowering capital expenditures and saving on floor space. The ability to produce both types of fabrics simultaneously increases production flexibility and efficiency, leading to higher throughput and reduced operational costs. Moreover, spunmelt machines are designed with high levels of automation, including PLC control and touch-screen interfaces, which streamline operations and minimize labor costs. This automation also contributes to consistent fabric quality, reducing waste and enhancing overall production efficiency.

When compared to other nonwoven technologies, such as airlaid or hydroentanglement, spunmelt machines offer distinct advantages. Airlaid systems, while effective for certain applications, typically involve higher raw material costs and require additional processes for bonding and finishing. Hydroentanglement, though producing high-quality fabrics, often involves more complex machinery and higher water consumption, which can translate into increased operational costs. In contrast, spunmelt machines, with their relatively straightforward processing requirements and efficient use of raw materials, present a more cost-effective solution for producing a wide variety of nonwoven fabrics.

The investment in a spunmelt machine also aligns well with current trends toward sustainability and efficiency. As the demand for eco-friendly and high-performance nonwoven materials grows, the ability to quickly adapt to changing market needs and produce a range of fabric types becomes increasingly valuable. Spunmelt technology’s ability to utilize 100% polypropylene granules and produce fabrics with precise denier and weight specifications meets these demands while supporting sustainable practices through reduced waste and energy consumption.

The decision to invest in a spunmelt machine should be guided by a comprehensive assessment of production needs, market demand, and cost considerations. While initial capital outlay for spunmelt machines may be significant, their long-term benefits, including reduced operational costs, high production flexibility, and alignment with sustainability trends, often outweigh these costs. By evaluating these factors, businesses can determine the most cost-effective nonwoven production technology for their specific requirements, ensuring a strategic investment that supports both short-term and long-term objectives.

English

English 中文简体

中文简体 русский

русский عربى

عربى