The flexibility of a spunbond nonwoven machine in adapting to various fabric weights and widths is a critical factor that determines its versatility and efficiency in production. This adaptability is achieved through several design features and operational adjustments that cater to the diverse requirements of different applications. The core advantage of the spunbond nonwoven machine lies in its ability to handle a broad range of fabric specifications without compromising on performance or quality.

Spunbond machines are engineered to manage varying fabric weights, typically ranging from 9 to 70 GSM. This wide range is made possible by the machine's adjustable process parameters and advanced control systems. For instance, the machine’s speed, which can vary from 9 to 500 meters per minute, is fine-tuned to accommodate different fabric weights. This ensures that the quality of the fabric remains consistent, whether producing lightweight materials for hygiene products or heavier fabrics for industrial uses. The integration of a slitter allows for precise cutting of the fabric into various widths, making it adaptable to specific requirements and enhancing its utility in different industries.

Moreover, the spunbond nonwoven machine’s ability to handle different filament deniers, ranging from 1.8 to 2.5 D, contributes to its flexibility. Adjustments in filament denier affect the fabric’s strength and texture, which the machine accommodates through precise control over spinning and bonding processes. This adaptability is further supported by the use of high-performance components, such as Siemens motors and ABB drivers, which provide reliable control over the machine's operations and enable it to maintain consistent output quality.

The machine's design incorporates a highly automated system controlled by a PLC with a touch-screen interface. This advanced control system allows for easy adjustments to the machine settings, facilitating quick changes between different fabric specifications. The high degree of automation not only simplifies operation but also enhances precision in fabric production, ensuring that the machine can efficiently switch between varying weights and widths with minimal downtime.

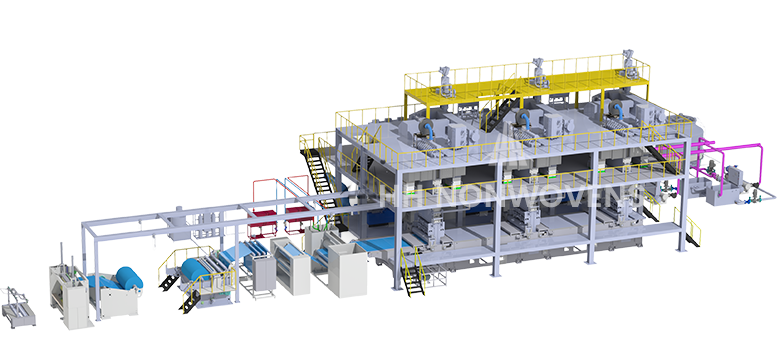

In addition to its adaptability, the spunbond nonwoven machine from JIASHAN HH Nonwovens Machinery Co., Ltd offers notable advantages in terms of structural stability and ease of operation. The use of CNC for producing main parts and dynamic balancing for rollers ensures smooth, high-speed operation, which is crucial for maintaining consistent fabric quality across different specifications. The machine’s robust build and advanced technology underscore its capability to meet diverse production needs while delivering reliable performance.

The flexibility of the spunbond nonwoven machine in adapting to different fabric weights and widths is a testament to its advanced engineering and operational versatility. Its ability to accommodate various specifications without sacrificing quality makes it an invaluable asset for manufacturers seeking to optimize their production processes and cater to a wide range of applications.

English

English 中文简体

中文简体 русский

русский عربى

عربى