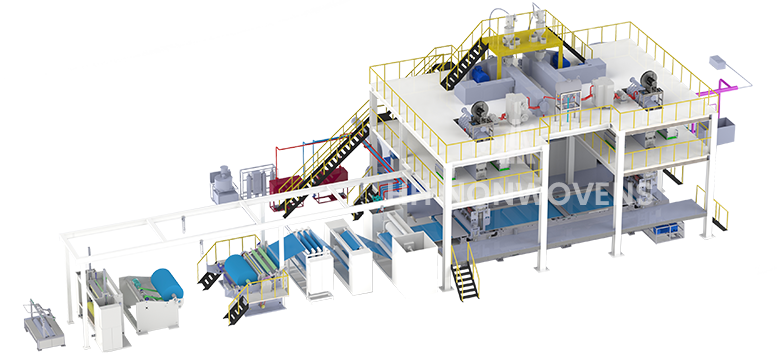

In the textile manufacturing, efficiency is paramount. Among the array of machinery powering this industry, Spunbond Nonwoven Machines stand out for their versatility and productivity.

Embarking on the journey of setting up a Spunbond Nonwoven Machine is akin to orchestrating a symphony of precision and innovation. From the initial installation to the triumphant launch of production, every step requires meticulous planning and execution.

The installation phase sets the cornerstone for seamless operation. Skilled technicians meticulously piece together the components, ensuring each bolt and joint is secure. Depending on the size and complexity of the machine, this process can span from several days to a couple of weeks. Every element, from the robust frame to the intricate control panels, is meticulously aligned to lay the groundwork for flawless performance.

With the machine assembled, the stage is set for commissioning – a crucial phase where meticulous attention to detail reigns supreme. Technicians embark on a journey of calibration and testing, meticulously fine-tuning each component to ensure optimal functionality. From the whirring of motors to the precision of rollers, every aspect is scrutinized to meet the highest standards. This meticulous process can take several days to a week, as technicians leave no stone unturned in their quest for perfection.

A well-trained operator is the linchpin of operational excellence. As the machine undergoes commissioning, operators undergo intensive training to master its intricacies. From understanding control interfaces to troubleshooting common issues, every aspect is covered with precision. While the duration of training may vary, ranging from a few days to a week, the goal remains constant – empowering operators to navigate the machine with confidence and expertise.

With installation complete, commissioning finalized, and operators armed with knowledge, the stage is set for the grand finale – production startup. Like a conductor leading an orchestra, operators fine-tune settings and feed raw materials into the machine with precision. Trial runs validate the production process, ensuring seamless operation from the outset. While the timeline for production startup may vary based on operator readiness and unforeseen challenges, the journey culminates in a triumphant launch of efficiency and productivity.

English

English 中文简体

中文简体 русский

русский عربى

عربى