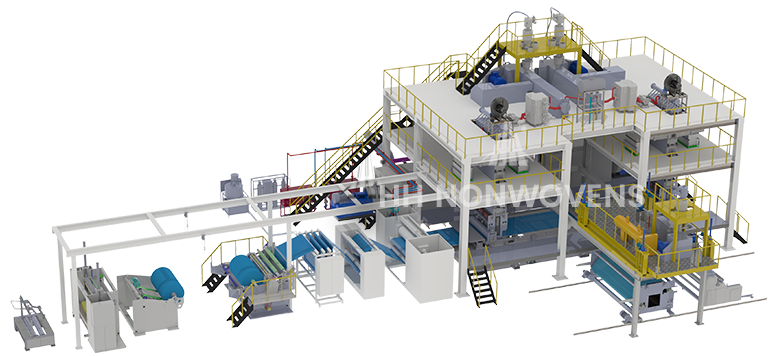

In the realm of nonwoven fabric production, versatility is the key to meeting the dynamic demands of various industries. Nonwoven spunmelt machines stand as pillars of innovation, offering manufacturers the flexibility to tailor their production to different types of nonwoven fabrics. But the burning question remains: Is it possible to adjust these machines for different types of nonwoven fabric production? Let's delve into the intricate workings of these machines to uncover the answer.

At the heart of nonwoven spunmelt machines lies a tapestry of adjustable parameters, each contributing to the seamless adaptation for diverse fabric production. From raw material feed to extrusion parameters, temperature settings to layering techniques, these machines offer a multifaceted toolkit for fabric customization.

The journey begins with the raw materials. Nonwoven spunmelt machines are adept at accommodating various raw materials, from polypropylene granules of differing grades to specialized additives. This versatility sets the stage for fabric innovation, allowing manufacturers to experiment with different materials to achieve desired properties.

Crucially, the extrusion process emerges as a pivotal arena for adjustment. By fine-tuning extrusion parameters, such as temperature and pressure, manufacturers can sculpt the characteristics of the fabric filaments. Whether aiming for fine-spun delicacy or robust strength, the extrusion process stands ready to adapt to the demands of different fabric types.

But the magic doesn't end there. Nonwoven spunmelt machines offer control over web formation, enabling manufacturers to dictate the thickness, density, and orientation of fibers within the fabric. This level of precision empowers manufacturers to craft fabrics tailored to specific applications, from lightweight hygiene products to heavy-duty industrial materials.

For those venturing into the realm of composite fabrics, nonwoven spunmelt machines offer a canvas for creativity. By adjusting layering techniques and integrating specialized equipment, manufacturers can seamlessly blend spunbond and meltblown layers to achieve unique properties such as enhanced filtration efficiency or superior barrier protection.

Of course, speed and tension control play pivotal roles in the fabric production process. Nonwoven spunmelt machines provide the flexibility to adjust machine speed and tension settings, allowing manufacturers to fine-tune the production process to suit the requirements of different fabric types. Whether racing to meet tight deadlines or delicately crafting intricate designs, these machines offer the agility needed to excel in a competitive market.

In conclusion, the answer to the question, "Is it possible to adjust nonwoven spunmelt machines for different types of fabric production?" is a resounding yes. With a wealth of adjustable parameters at their disposal, manufacturers can unleash their creativity and adaptability to meet the diverse needs of various industries. From raw material selection to extrusion finesse, web formation to layering mastery, nonwoven spunmelt machines stand as beacons of innovation, empowering manufacturers to weave their visions into reality.

English

English 中文简体

中文简体 русский

русский عربى

عربى